Choosing between lyocell vs viscose can feel overwhelming, especially when both fabrics promise softness, breathability, and a more environmentally conscious alternative to synthetics. But while they originate from similar cellulose sources, their stories take very different paths.

Below, we explore how lyocell and viscose differ in origin, production, durability, cooling performance, sustainability, care requirements, and how they truly feel against the skin.

Comparing Materials and Origins

What Is Lyocell Made Of? What Is Viscose Made Of?

Both lyocell and viscose come from wood pulp, usually harvested from sustainable forests. They fall under the broader category of rayon (so yes - viscose is rayon).

Lyocell is part of a newer generation of eucalyptus-based fibers created with cleaner, lower-impact chemistry, offering a more refined and modern approach.

They’re both regenerated cellulosic fibers, but lyocell represents a newer, cleaner generation of the technology.

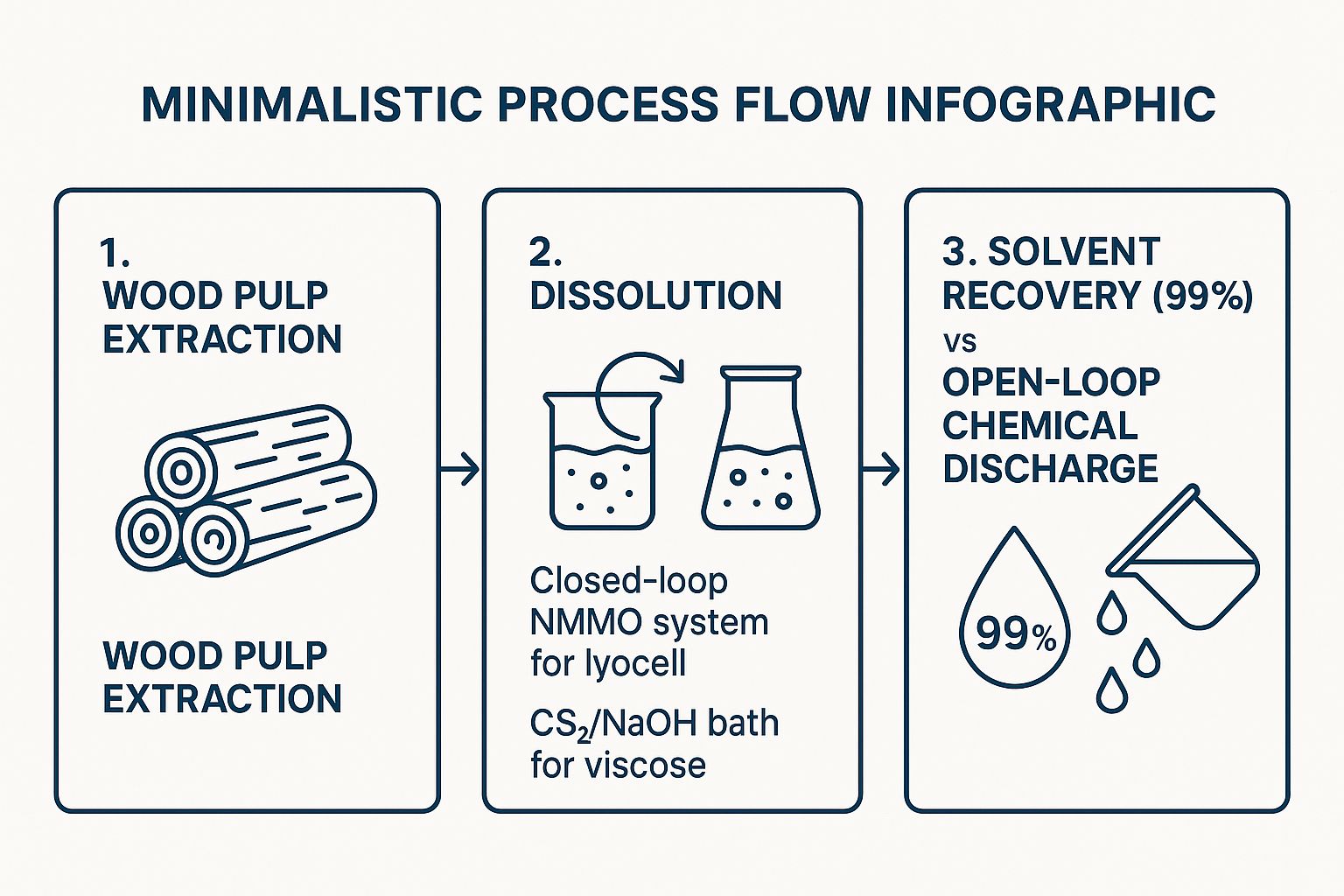

How They Are Made: Production Process

Lyocell Production

Lyocell uses a modern closed-loop system that recovers over 99% of the solvent used.

The approach mirrors many principles behind today’s most sustainable eucalyptus materials, producing a fiber that is gentle on both skin and planet.

Viscose Production

Viscose uses an older open-loop system involving carbon disulfide and caustic soda which are chemicals that can pollute waterways if not properly treated.

Here's a breakdown of the pros and cons of each production method:

Lyocell:

- Pros: Environmentally friendly due to closed-loop system and non-toxic solvents, requires less water and energy compared to viscose.

- Cons: Higher production costs compared to viscose, limited manufacturing facilities globally.

Viscose:

- Pros: Lower production costs, established infrastructure and widespread availability.

- Cons: Environmental concerns due to chemical discharge and higher water and energy consumption.

Both:

- Pros: Utilize a renewable resource (wood pulp).

- Cons: Energy-intensive manufacturing process.

5 Key Comparison Factors: Lyocell vs Viscose

Both lyocell and viscose offer softness and breathability, but they support comfort in very different ways.

1. Moisture Management & Breathability

A fabric’s ability to stay cool and dry influences everything - from how peacefully you sleep to how comfortable you feel in warm weather.

Lyocell Advantages

Lyocell can absorb up to 50% more moisture than cotton.

It draws moisture away from the skin and releases it quickly into the air, creating a cool, fresh feeling throughout the night.

This makes lyocell a wonderful choice for:

-

Hot sleepers

-

Warm or humid climates

-

Menopausal women navigating night sweats

-

Anyone who wants a cool-to-the-touch bedding experience

For deeper comparison, check out how eucalyptus, bamboo, and cotton sheets differ in cooling and moisture control.

💡Pros: Exceptional moisture management, stays dry longer, temperature regulating.

💡Cons: More expensive than traditional moisture-wicking synthetics.

Viscose Advantages

Viscose is breathable and light, but it holds onto moisture longer, especially in humidity.

This can make the fabric feel clingy, heavy, or slightly damp against the skin.

Viscose works best for:

-

Mild to warm climates

-

Everyday clothing that benefits from a soft, flowing drape

-

Occasional wear rather than heavy perspiration condition

💡Pros: Natural breathability, comfortable in moderate climates.

💡Cons: Can feel clammy when wet, slower drying.

2. Durability & Fiber Strength

Durability affects whether a fabric becomes a long-term comfort companion or something delicate that needs extra attention.

Lyocell Durability

Lyocell fibers remain strong, even when wet.

This creates a fabric that:

-

Holds its shape beautifully

-

Resists pilling

-

Wrinkles less

-

Maintains softness with frequent washing

This reliability makes lyocell especially well-suited for bedding that’s washed regularly.

You may also find our guide on how often TENCEL™ (lyocell) sheets should be washed to stay fresh and last longer helpful.

💡Pros: Long-lasting, maintains quality over time, resists pilling, strong wet strength, excellent shape retention.

💡Cons: Higher initial cost may not suit all budgets.

Viscose Durability

Viscose feels soft and elegant but becomes weaker when wet, which means it needs more mindful care.

It may:

-

Stretch or shrink

-

Pill more easily

-

Lose its original shape over time

Viscose is best for gentle-use garments where drape and softness matter more than longevity.

💡Pros: Initially soft hand feel, drapes well, more affordable.

💡Cons: Weakens significantly when wet, prone to shrinkage, more prone to pilling, shorter lifespan.

Tips for consumers:

- Consider lyocell for bedding, underwear, and other items you wash regularly. Its durability will ensure these pieces last longer, ultimately saving you money in the long run.

- Avoid harsh agitation and wringing to prevent damage.

- Follow care instructions carefully and consider pre-shrinking viscose fabric before sewing.

- Lighter weights for flowing garments, heavier weights for structured pieces.

3. Sustainability & Environmental Impact

Both fibers begin with trees, but their environmental footprints differ significantly.

Why Lyocell Is More Sustainable

Lyocell is produced in a closed-loop system, which recaptures over 99% of the solvent used.

It is considered one of the most eco-conscious fabrics because it is:

-

Biodegradable

-

Made with low-toxicity solvents

-

Water efficient

-

Sourced from responsibly managed forests

Is Lyocell Toxic?

No. The solvent used (NMMO) is safe and nearly completely recovered during production.

To go deeper into eco-friendly fiber production, see: why many conscious brands prioritize TENCEL™ lyocell for low-impact manufacturing.

Where Viscose Falls Short

Traditional viscose production requires more chemicals and water.

This contributes to:

-

Higher environmental stress

-

Risk of chemical discharge

-

Higher energy use

-

Potential deforestation if sourcing is not regulated

Newer options like EcoVero™ offer improvements, but the overall process still has a heavier impact than lyocell.

4. Fabric Hand Feel & Drape

How a fabric rests against your skin shapes the emotional experience of wearing or sleeping in it.

Does lyocell feel like viscose?

They can feel similar at first, but lyocell stays smoother and cooler over time.

The Feel of Lyocell

Lyocell has a smooth, cool touch that feels quietly luxurious.

Its texture stays consistent over time and becomes even softer with washing.

Perfect for:

-

People who love cool, silky bedding

-

Sensitive skin

-

Those who prefer structure without stiffness

If you’re exploring skin-friendly fabrics, you may find value in: a guide to the best fabrics for sensitive skin and eczema-prone sleepers.

The Feel of Viscose

Viscose has a soft, flowing drape that moves beautifully.

It feels airy and elegant, but it may lose some of its initial softness with repeated wear.

Perfect for:

-

Dresses, skirts, and relaxed silhouettes

-

Lightweight tops and flowing layers

-

Clothing that benefits from movement and drape

5. Cooling, & Comfort Experience

Lyocell and viscose both offer softness, but they support comfort in different ways.

Cooling & Temperature Regulation

Lyocell is especially supportive for:

-

Hot sleepers

-

Warm or humid climates

-

People who experience night sweats

Viscose works best for:

-

Mild to warm climates

-

Sleepers who don’t overheat easily

-

Lightweight garments or bedding used seasonally

Comfortability Comparison

Lyocell has a smooth, calming feel with a naturally luxurious finish. Its texture stays consistent over time, even with frequent washing, and it maintains a gentle drape without clinging.

While, viscose is soft and fluid, often compared to silk in its drape. It feels lovely at first touch, but its softness may change over time, especially after repeated laundering.

💡Lyocell stays smooth, cool, and consistent.

💡Viscose is initially soft and flowing but can become less stable over time.

Care Requirements

Thoughtful care can extend the life of any fabric, but lyocell and viscose respond differently to washing and wear.

Lyocell is forgiving and stable, while viscose needs more gentle handling to maintain its drape and softness.

Lyocell Care

Lyocell is designed for everyday ease.

It stays strong when wet, resists stretching, and responds well to simple care routines.

Care tips:

-

Wash on a gentle cycle

-

Use cool water

-

Air dry for best results

-

Steam lightly to release wrinkles, if needed

Because of its durability, lyocell is an excellent choice for bedding and garments that see frequent washing.

To explore care routines for eucalyptus lyocell bedding, see: a simple care guide for TENCEL™ eucalyptus sheets.

Viscose Care

Viscose becomes fragile when wet, which is why it needs a softer touch during laundering.

Care tips:

-

Avoid twisting, wringing, or aggressive washing

-

Use cool water on a delicate cycle

-

Air dry to prevent misshaping

-

Iron on low to restore smoothness

Viscose can be beautiful and fluid, but it asks for care that reflects its delicate structure.

Lyocell vs Other Fabrics

Understanding how lyocell compares to other common materials can help you choose fabrics that support the rest, comfort, and sustainability values you care about.

Lyocell vs Cotton

Cotton is breathable, familiar, and widely used—but lyocell offers a more elevated experience.

Lyocell advantages over cotton:

-

More breathable and better at regulating temperature

-

Superior moisture-wicking

-

Naturally smoother and silkier

-

Requires less water and fewer chemicals to produce

This makes lyocell a beautiful option for anyone who loves the simplicity of cotton but wants a cooler, softer, and more eco-conscious alternative.

Lyocell vs Polyester

Polyester is durable and budget-friendly, but it is synthetic and does not breathe the way natural fibers do.

Lyocell advantages over polyester:

-

No microplastic shedding

-

Cooler and significantly more breathable

-

Naturally odor-resistant

-

Friendlier for sensitive skin

Lyocell supports a healthier home environment, especially for sleepers who prefer natural materials.

Viscose vs Modal

Modal is a second-generation form of viscose.

It is stronger, smoother, and better at holding its shape than standard viscose, but the production process still carries environmental challenges.

Key differences:

-

Modal is more durable than viscose

-

Both are silky and drapey

-

Neither is as sustainable as lyocell

-

Modal offers better long-term softness than viscose

For those prioritizing low-maintenance luxury and sustainability, lyocell still stands out as the top performer.

Lyocell vs Viscose Fabric Comparison Table

| Category | Lyocell | Viscose |

| Source | Sustainably sourced wood pulp (often eucalyptus) | Wood pulp including bamboo or mixed tree species |

| Production | Clean closed-loop process; low chemical impact | Older open-loop process; higher chemical use |

| Breathability | Very breathable; stays cool + dry | Breathable but holds moisture longer |

| Durability | Strong when wet; resists pilling; holds shape | Weaker when wet; prone to stretching + pilling |

| Sustainability | Biodegradable; low-toxicity; water-efficient | Biodegradable but more resource-intensive |

| Feel | Smooth, cool, consistent over time | Soft, fluid drape; may lose softness |

| Best For | Hot sleepers, sensitive skin, bedding | Flowing clothing, mild climates |

Making the Right Choice: Lyocell or Viscose?

If you value sustainability, durability, and a cool, serene sleep environment, lyocell - especially TENCEL™ - is the stronger choice.

If affordability or fluid drape is your priority, viscose offers a beautiful hand feel at a lower cost, though with more delicate care needs.